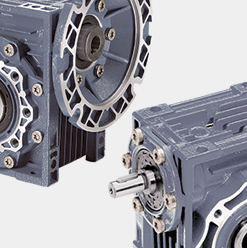

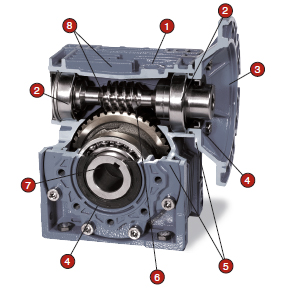

Worm Gear Series variants

Worm Gear Series variants

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim. Aliquam lorem ante, dapibus in, viverra quis, feugiat a, tellus. Phasellus viverra nulla ut metus varius laoreet. Quisque rutrum. Aenean imperdiet. Etiam ultricies nisi vel augue. Curabitur ullamcorper ultricies nisi. Nam eget dui. Etiam rhoncus. Maecenas tempus, tellus eget condimentum rhoncus, sem quam semper libero,

Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim. Aliquam lorem ante, dapibus in, viverra quis, feugiat a, tellus. Phasellus viverra nulla ut metus varius laoreet. Quisque rutrum. Aenean imperdiet. Etiam ultricies nisi vel augue. Curabitur ullamcorper ultricies nisi. Nam eget dui. Etiam rhoncus. Maecenas tempus, tellus eget condimentum rhoncus, sem quam semper libero, it amet adipiscing sem neque sed ipsum. Nam quam nunc, blandit vel, luctus pulvinar, hendrerit id, lorem. Maecenas nec odio et ante tincidunt tempus. Donec vitae sapien ut libero venenatis faucibus. Nullam quis ante. Etiam sit amet orci eget eros faucibus tincidunt. Duis leo. Sed fringilla mauris sit amet nibh. Donec sodales sagittis magna. Sed consequat, leo eget bibendum sodales, augue velit cursus nunc.

Available Worm Gear Reducers: NWM Motor Input Flange | NWS Input Shaft

Aluminum alloy housing with patented heat sink design provides greater surface area and higher thermal capacity than traditional cast-iron housings

Aluminum alloy housing with patented heat sink design provides greater surface area and higher thermal capacity than traditional cast-iron housings- Two bearings along the input shaft prevent leaks and contribute to flexibility in mounting. High quality bearings increase reducer life versus worm reducers with a bushing on the input

- NEMA and IEC motor inputs available for greater customer flexibility

- Double-lip oil seals aid the reducer’s thermal capacity and extended the reducer’s oil life

- Use of O-rings on the input flange and output cover prevents leaks more eff ectively than a paper gasket

- Hardened worm shaft gives increased durability versus forged worm shafts

- Standard hollow output bore and optional plug-in shafts provide greater flexibility in ordering and reduced inventory

- Polyester epoxy paint applied on the inside and outside of the gearcase protects against rust

- There is no breather for size 30B to 90B, there is breather for size 110B and 130B. NWM and NWS are universal mounting, sealed for life, maintenance-free reducers

- No compression chamber required, preventing leaks and the risk of oil oxidation and contamination, and contributing to mounting flexibility

- Automated manufacturing process from an ISO 9001 certifi ed company assures quality, reliable gearing

- Aluminum units are prefilled with synthetic oil; cast iron units are prefilled with mineral oil