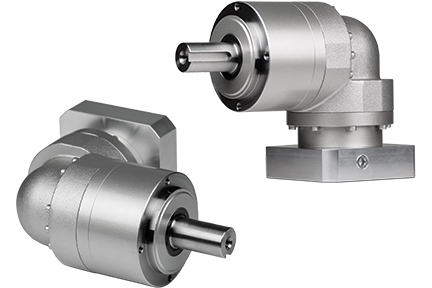

The right angle equivalent to the VRL series, the EVL provides our customers with an excellent solution when space and clearance are a serious limitation. Helical planetary gears team up with spiral bevel gears to provide a product with robust internal construction, smooth operation and high torque density. 6 arc-min backlash allows the VRL to be applied to a wide range of applications where accuracy and dynamics are in play, but cost is of concern.

The right angle equivalent to the VRL series, the EVL provides our customers with an excellent solution when space and clearance are a serious limitation. Helical planetary gears team up with spiral bevel gears to provide a product with robust internal construction, smooth operation and high torque density. 6 arc-min backlash allows the VRL to be applied to a wide range of applications where accuracy and dynamics are in play, but cost is of concern.

The EVL is a solid choice for servo applications in packaging, handling and automation systems. A variety of standard wash down and food grade options are available, making it an attractive option for the toughest environments. We offer the broadest selection of frame sizes and ratios, giving our customers more flexibility than ever before. Industry standard mounting dimensions allow the EVL to be implemented in legacy machine designs, saving our customers valuable time.

Available Frame Sizes: 070 | 090 | 120 | 155 | 205 | 235

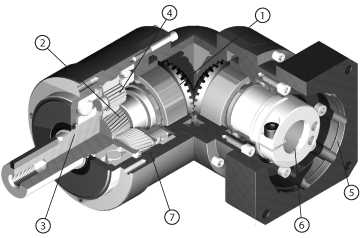

- Right angle bevel gear configuration allows motor to be mounted at a 90 degree position from the gearbox, saving space

- Carburized helical gears with proprietary secondary finishing process for higher accuracy and smooth, quiet operation. 40% higher tooth surface area than the industry standard

- One piece output shaft and planet carrier with two bearings straddling the planet gears. Higher stiffness, torque capacity and safety factor, with guaranteed alignment of gearing

- Uncaged needle roller bearings provide excellent torque density and torsional rigidity. 43% larger bearing surface area compared to the rest of the industry

- Optimized mounting system with active centering on motor pilot diameter guarantees alignment of motor. Motor can be installed in any orientation

- True concentric motor shaft clamping connection, optimized for your specific motor. Reduced inertia for dynamic performance and balanced for high speed operation

- Ring gear machined directly into the housing, not welded or pressed in. Provides greater concentricity and elimination of speed fluctuation

*1) Motor mounting code varies depending on the motor. Use the selection tool link below to configure the code.