Nidec Drive Technology Corporation continues to press forward with the development of high-precision gear technology that fills the evolving needs of our customer base. The announcements for any recent development efforts within our company are updated and logged on this page. If you have any questions or require additional information about any of the products mentioned within these press releases, please do not hesitate to contact us.

As we launch any new products to market, Nidec DTC stands firmly behind the exceptional quality and value that we are delivering to our customers. Ultimately, it is this quality and value that is critical in order for our OEM customers to maintain their competitiveness in the global arena.

Setting the Industry Standard for Washdown Applications

Nidec Drive Technology Corporation is a global diversified manufacturer of motion control and power transmission solutions, including high precision planetary gearboxes, cycloidal gearboxes, rotary indexers and mechanical variable speed drives, as well as is a leading manufacturer and supplier of speed, force and torque testing and inspection instrumentation for laboratory research, quality control and process control applications. Today, Nidec DTC is proud to extend our product offering with the only industry IP69K right-angle worm gearbox that is 3A, NSF and EHEDG certified with our EJS Series.

Nidec Drive Technology Corporation is a global diversified manufacturer of motion control and power transmission solutions, including high precision planetary gearboxes, cycloidal gearboxes, rotary indexers and mechanical variable speed drives, as well as is a leading manufacturer and supplier of speed, force and torque testing and inspection instrumentation for laboratory research, quality control and process control applications. Today, Nidec DTC is proud to extend our product offering with the only industry IP69K right-angle worm gearbox that is 3A, NSF and EHEDG certified with our EJS Series.

Hygienic applications require a stainless steel design. The EJS Series right-angle worm gearbox is now available to suite your needs. With a smooth, rounded surface design the EJS series eliminates free-standing water and prevents bacteria growth with its IP69K protection. The EJS series is the perfect solution for any washdown application.

For more details about the new EJS product line contact us today!

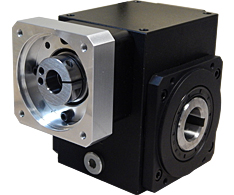

The Ultimate Space Saving Right Angle Gearbox

Itasca, Illinois January 1, 2015 – Nidec Drive Technology Corporation has established itself as a leading supplier of drive technology and precision power transmission solutions to the industrial marketplace. With traditional roots that began imbedded in the development of mechanical variable speed powertrains, Nidec DTC has grown into a more diverse manufacturer of high precision products. Today, Nidec DTC is proud to offer the market the ultimate space saving solution for tight situations—the EVT series.

Itasca, Illinois January 1, 2015 – Nidec Drive Technology Corporation has established itself as a leading supplier of drive technology and precision power transmission solutions to the industrial marketplace. With traditional roots that began imbedded in the development of mechanical variable speed powertrains, Nidec DTC has grown into a more diverse manufacturer of high precision products. Today, Nidec DTC is proud to offer the market the ultimate space saving solution for tight situations—the EVT series.

The EVT series right angle with flange output is ideal for challenging applications that require high accuracy, torsional stiffness and moment loading. This gearbox is optimized to handle larger radial and thrust forces found in applications within the machine tool, aerospace or robotics industries. The compactness of this product gives our customers space savings and design flexibility that is unsurpassed in the market.

For more details about the new EVT product line contact us today!

EJ Series

Nidec Drive Technology Corporation has been at the forefront of developing gear technology to fill the requirements of our customer base and has expanded its product offering to include a variety of precision worm gearboxes: our EJ Series. These servo grade gearheads are ideal for challenging motion control applications requiring an efficient, quiet and smooth running drive.

Nidec Drive Technology Corporation has been at the forefront of developing gear technology to fill the requirements of our customer base and has expanded its product offering to include a variety of precision worm gearboxes: our EJ Series. These servo grade gearheads are ideal for challenging motion control applications requiring an efficient, quiet and smooth running drive.

Three variants are offered to match a wide range of customer applications: EJP, EJH & EJM. Each series incorporates a globoidal worm gear mesh design resulting in optimal torque density, low backlash, high overload protection and high torsional rigidity in a compact space envelope. Mounting options including hollow shaft, flange mount and shrink disc provide the ultimate level of flexibility with various machine interfaces.

The EJ series is well suited for applications within the metal forming and general automation industries, but is also offered in a variety of wash down options to meet the demands of the food & beverage market. Please contact us for further details or applications assistance.

For more details please contact Nidec Drive Technology Corporation.

Planetary Reducer with Exceptional Positional Accuracy

Nidec Drive Technology Corporation is proud to announce the release of its new VRT series. The VRT series sets a new standard for servo motor gear reduction applications that require exceptional torsional rigidity and high positional accuracy. The hub-style output of the reducer has an ISO9409 mounting interface and provides superior flexibility in the mounting of pinions, pulleys, and turntables. The reducer is offered in seven different frame sizes and in a multitude of 1-stage and 2-stage ratios. The larger frame sizes include tapered roller bearings that have better radial and axial load handling characteristics than those bearing commonly utilized in competitor’s design, so improved ratings over those products within its competitive class.

Nidec Drive Technology Corporation is proud to announce the release of its new VRT series. The VRT series sets a new standard for servo motor gear reduction applications that require exceptional torsional rigidity and high positional accuracy. The hub-style output of the reducer has an ISO9409 mounting interface and provides superior flexibility in the mounting of pinions, pulleys, and turntables. The reducer is offered in seven different frame sizes and in a multitude of 1-stage and 2-stage ratios. The larger frame sizes include tapered roller bearings that have better radial and axial load handling characteristics than those bearing commonly utilized in competitor’s design, so improved ratings over those products within its competitive class.

With a backlash rating less than 3 arc-minutes and exceptional torque handling capabilities, the VRT is a high performance, compact, and robust solution for equipment manufacturers. The VRT is often used for larger indexing applications and dial tables, commonly found in metal forming, filling equipment, packaging machinery, and assembly automation systems.

For more details please contact Nidec Drive Technology Corporation.

Now Assembling Food and Washdown Duty Gearbox options in Itasca, Illinois Build Center

As the global marketplace becomes increasingly competitive, Nidec Drive Technology Corporation continues to raise the bar in terms of product quality, variety, flexibility, and availability – providing a real value to our customers. Our new Wash-down and Food Grade compatible reducers serve as another good example where Nidec DTC is delivering improved value to our customers.

As the global marketplace becomes increasingly competitive, Nidec Drive Technology Corporation continues to raise the bar in terms of product quality, variety, flexibility, and availability – providing a real value to our customers. Our new Wash-down and Food Grade compatible reducers serve as another good example where Nidec DTC is delivering improved value to our customers.

Our most common inline and right-angle planetary and cycloidal frame sizes and ratios can now be quickly assembled with a variety of Washdown or Food Grade Duty options from our North America Kit Build Facility. Features can be selected a la carte, depending on the customer’s specifications and factory environment preferences. Small quantity orders can be assembled, tested, and shipped within 2–4 days. For all other series, frame size and ratio combinations; please contact Nidec DTC for price and availability from our main manufacturing facility.