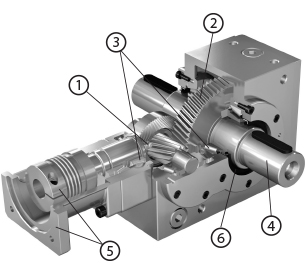

TwinGear harnesses the power of two with its hypoid primary stage and helical secondary stage. This gear train redefines power, compactness and precision, setting benchmarks in the industry. High torsional stiffness and backlash <6 arc-minutes and make it a contender in dynamic motion control applications. With ratios spanning from 15-75:1 and maximum acceleration torque as high as 11,250Nm, TwinGear can be applied confidently across a myriad of applications.

TwinGear harnesses the power of two with its hypoid primary stage and helical secondary stage. This gear train redefines power, compactness and precision, setting benchmarks in the industry. High torsional stiffness and backlash <6 arc-minutes and make it a contender in dynamic motion control applications. With ratios spanning from 15-75:1 and maximum acceleration torque as high as 11,250Nm, TwinGear can be applied confidently across a myriad of applications.

Our customers demanded a more compact helical bevel design and we answered. TwinGear can fit in the narrowest space envelopes. Solid shaft, dual shaft, hollow shaft and shrink disc mounting interfaces provide the ultimate flexibility for machine designers. Rated up to 8,000rpm, this product outperforms in high speed, continuous duty applications while staying quiet and cool.

Literature Download: TwinGear Series

CAD Model Download: TwinGear Series

- Hypoid primary stage with optimized contact pattern for uniform load distribution, low noise and high transmission accuracy

- Helical secondary stage for high torque generation

- Tapered roller bearings at input and output for high radial and axial load capacity

- Four output mounting styles for maximum flexibility: Keyed solid shaft, keyed dual shaft, keyed hollow shaft and hollow shrink disc

- Simple, low inertia connection to various servo motors using adapter flange and stiff zero backlash coupling

- Output seal allows for IP64 protection

* Motor mounting code varies depending on the motor. Contact us to configure the code.