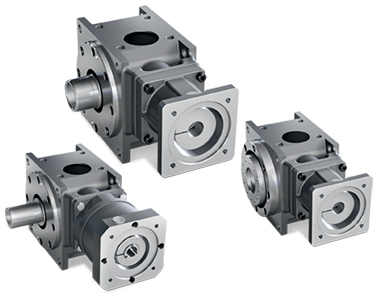

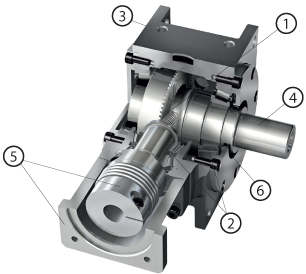

DynaGear was developed for highly dynamic servo applications requiring exceptional accuracy and efficiency in a compact footprint. DynaGear uses optimized hypoid gears for high, smooth torque transfer with backlash as low as < 2 arc-min. Tapered roller bearings on the input and output sides of the gearbox absorb high radial and axial loads, ensuring long service life. A planetary input is

used to achieve higher ratios.

DynaGear was developed for highly dynamic servo applications requiring exceptional accuracy and efficiency in a compact footprint. DynaGear uses optimized hypoid gears for high, smooth torque transfer with backlash as low as < 2 arc-min. Tapered roller bearings on the input and output sides of the gearbox absorb high radial and axial loads, ensuring long service life. A planetary input is

used to achieve higher ratios.

DynaGear uses a weight efficient one-piece aluminum housing for high stability under load. Versatile output mounting options include solid shaft, hollow shaft, dual shaft and robot flange. The extremely compact design provides significant space savings for small installation envelopes. Lubricated for life, DynaGear is a reliable maintenance-free solution.

Literature Download: DynaGear Series

CAD Model Download: DynaGear Series

- Hypoid gearing with optimized contact pattern for uniform load distribution

- Tapered roller bearings at input and output for high radial and axial load capacity

- Weight efficient one-piece aluminum housing ensuring high stability under load

- Four output mounting styles for maximum flexibility: Solid shaft, hollow shaft, dual shaft, ISO 9409-1 robot flange

- Simple, low inertia connection to various servo motors using adapter flange and stiff zero backlash coupling

- Output seal allows for IP64 protection

* Motor mounting code varies depending on the motor. Contact us to configure the code.