Nidec Drive Technology Statement on COVID-19

March 16, 2020

Dear Valued Customers, Suppliers and Partners,

The impact caused by COVID-19 to our local and the global community, along with the response, is evolving rapidly. Nidec Drive Technology Corporation is monitoring the situation closely and ensuring internal measures are put in place to protect the health and safety of our employees while at the same time serving our customers’ needs.

As a global manufacturing company focused on providing the highest level of customer service, Nidec DTC is committed to ensure there is no disruption of our products and services from our internal manufacturing, or any of our supply chain partners.

Nidec DTC has a large inventory of products on the shelf, multiple sources for nearly every component and manufacturing capacity across multiple facilities available to handle our existing and future customers’ needs. We do not anticipate any disruptions in our ability to supply our gearing products to our customer base.

Nidec DTC has already taken steps to avoid the spread of the COVID-19 virus, including:

- Establishing a COVID-19 committee to review all information and establish the best response for the well-being of our company and customers

- Sanitizing our work environment by additional cleaning to disinfect all surfaces and implementing hand sanitizing stations throughout our offices, manufacturing and warehousing areas

- Implementing remote work for office staff to be able to handle normal administrative functions including phones, order processing, engineering, technical support and accounting

- Manufacturing continuation through isolated work zones: manufacturing personnel are being trained to operate in an environment that limits their interaction with other teammates. This isolation includes the restriction of movement to common areas; limits on the sharing of tools, machines, or other processes; and frequent cleaning.

- Stopping all travel

- Prohibiting visitors unless critical and approved by senior management

Feel free to contact us at 630-924-7138 or drives@nidec-shimpo.com if you have any questions, or if we can be of any assistance. We are here to support you and appreciate your continued support.

2021 and 2022 Upcoming Events

Nidec Drive Technology participates in numerous trade shows and industry events throughout the year. Stop by our booth at one of our upcoming trade shows or events.

Press Release: 06/01/17

Nidec Drive Technology Corporation moves into their new location in Glendale Heights, Illinois

We are proud to announce that Nidec DTC has moved into their new location in Glendale Heights, Illinois! The relocation was an important next step in order to handle the rapid growth that Nidec DTC is currently experiencing and to help facilitate our long-term expansion plans.

The new building provides increased space and infrastructure to increase our production capacity significantly for our many gear technologies. The space will enable Nidec DTC to have better capabilities to design and to customize our products for the local market.

Our new robotic gear technologies will have a strong development emphasis during the next 5 – 7 years. These products will require much more direct customer support and application engineering at the design stage. Nidec DTC plans to make significant investment in our technical resources and test capabilities to support our local customers as this market continues to emerge. The new building will nicely accommodate that vision.

The new address and contact information for our North American headquarters is the following;

Nidec Drive Technology Corporation

175 Wall Street,

Glendale Heights, IL 60139, USA

Toll-free: (800) 237-7079

Local: (630) 924-7138

Press Release: 01/01/16

Setting the Industry Standard for Washdown Applications

Nidec Drive Technology Corporation is a global diversified manufacturer of motion control and power transmission solutions, including high precision planetary gearboxes, cycloidal gearboxes, rotary indexers and mechanical variable speed drives, as well as is a leading manufacturer and supplier of speed, force and torque testing and inspection instrumentation for laboratory research, quality control and process control applications. Today, Nidec DTC is proud to extend our product offering with the only industry IP69K right-angle worm gearbox that is 3A, NSF and EHEDG certified with our EJS Series.

Nidec Drive Technology Corporation is a global diversified manufacturer of motion control and power transmission solutions, including high precision planetary gearboxes, cycloidal gearboxes, rotary indexers and mechanical variable speed drives, as well as is a leading manufacturer and supplier of speed, force and torque testing and inspection instrumentation for laboratory research, quality control and process control applications. Today, Nidec DTC is proud to extend our product offering with the only industry IP69K right-angle worm gearbox that is 3A, NSF and EHEDG certified with our EJS Series.

Hygienic applications require a stainless steel design. The EJS Series right-angle worm gearbox is now available to suite your needs. With a smooth, rounded surface design the EJS series eliminates free-standing water and prevents bacteria growth with its IP69K protection. The EJS series is the perfect solution for any washdown application.

For more details about the new EJS product line contact us today!

Press Release: 01/01/15

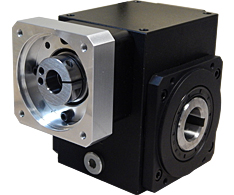

The Ultimate Space Saving Right Angle Gearbox

Itasca, Illinois January 1, 2015 – Nidec Drive Technology Corporation has established itself as a leading supplier of drive technology and precision power transmission solutions to the industrial marketplace. With traditional roots that began imbedded in the development of mechanical variable speed powertrains, Nidec DTC has grown into a more diverse manufacturer of high precision products. Today, Nidec DTC is proud to offer the market the ultimate space saving solution for tight situations—the EVT series.

Itasca, Illinois January 1, 2015 – Nidec Drive Technology Corporation has established itself as a leading supplier of drive technology and precision power transmission solutions to the industrial marketplace. With traditional roots that began imbedded in the development of mechanical variable speed powertrains, Nidec DTC has grown into a more diverse manufacturer of high precision products. Today, Nidec DTC is proud to offer the market the ultimate space saving solution for tight situations—the EVT series.

The EVT series right angle with flange output is ideal for challenging applications that require high accuracy, torsional stiffness and moment loading. This gearbox is optimized to handle larger radial and thrust forces found in applications within the machine tool, aerospace or robotics industries. The compactness of this product gives our customers space savings and design flexibility that is unsurpassed in the market.

For more details about the new EVT product line contact us today!

Press Release: 12/01/14

New Motion Analyzer Web Tool Helps Machine Builders Design Motion Control Systems, Reduce Time-to-Market

Itasca, Illinois December 1, 2014 – Rockwell Automation has rebuilt their Motion Analyzer software as a Web tool. The tool offers new user-friendly features and a vastly expanded product catalog to help engineers more easily specify, design and validate complete motion control systems.

Itasca, Illinois December 1, 2014 – Rockwell Automation has rebuilt their Motion Analyzer software as a Web tool. The tool offers new user-friendly features and a vastly expanded product catalog to help engineers more easily specify, design and validate complete motion control systems.

The Motion Analyzer Web tool is cloud-based, allowing users to access, update and collaborate on projects stored in a single location, reducing version control issues and the need to share project files back and forth. A cloud-based platform also means users are no longer limited by the processing speed of their computers when designing systems for more complex applications. The tool’s new browser-style format allows users to filter, review and compare products and general pricing, similar to search capabilities on popular e-commerce sites.

“Incorrectly sizing a motion system not only generates unnecessary costs in wasted engineering time and re-stocking fees, but it can greatly slow a machine’s time-to-market,” said Michael Lennard, product manager, Motion Solutions, Rockwell Automation. “The latest Motion Analyzer release is an evolution of the platform that is more collaborative, expansive and easy to use. When engineers can quickly create and examine complete motion control systems within a single platform, they can spend more time innovating and improving their machines.”

The Motion Analyzer Web tool provides machine builders access to a wider range of motion control products than ever before. It now incorporates products from nine Rockwell Automation PartnerNetwork Encompass product partners. Using the Motion Analyzer Web tool, engineers can determine a system’s specifications, evaluate multiple products, finalize the design and create a bill of materials.

As a Rockwell Encompass partner since 2010, Nidec DTC collaborates closely with Rockwell on providing high quality, complete motion control solutions to machine builders across the globe. The very best of the Nidec DTC product line is available on the newly rebuilt Motion Analyzer software. Find the best solution for your application today!

To specify Nidec DTC products for your application, click here.

Press Release: 07/27/14

EJ Series

Nidec Drive Technology Corporation has been at the forefront of developing gear technology to fill the requirements of our customer base and has expanded its product offering to include a variety of precision worm gearboxes: our EJ Series. These servo grade gearheads are ideal for challenging motion control applications requiring an efficient, quiet and smooth running drive.

Nidec Drive Technology Corporation has been at the forefront of developing gear technology to fill the requirements of our customer base and has expanded its product offering to include a variety of precision worm gearboxes: our EJ Series. These servo grade gearheads are ideal for challenging motion control applications requiring an efficient, quiet and smooth running drive.

Three variants are offered to match a wide range of customer applications: EJP, EJH & EJM. Each series incorporates a globoidal worm gear mesh design resulting in optimal torque density, low backlash, high overload protection and high torsional rigidity in a compact space envelope. Mounting options including hollow shaft, flange mount and shrink disc provide the ultimate level of flexibility with various machine interfaces.

The EJ series is well suited for applications within the metal forming and general automation industries, but is also offered in a variety of wash down options to meet the demands of the food & beverage market. Please contact us for further details or applications assistance.

For more details please contact Nidec DTC.

Press Release: 04/25/14

Release of our new High Precision Gear Technology Catalog

Nidec Drive Technology Corporation has updated and released a comprehensive catalog covering its full product range of servo motor grade planetary gear reducers. The new catalog includes thorough performance data and drawings for all inline, and right-angle reducers, and hollow bore rotary actuators. Some of the content added to the 2014 version of the catalog are the economy series, VRSF and right-angle NEV, the expanded frames size offering, the food and washdown duty options, and a more thorough explanation on motor adapter variety and dimensions.

The catalog serves as a great reference tool for any engineer involved in the specification of gear reduction for motion control applications. It also provides a brief tutorial of the Nidec DTC Online Selection Tool. The high precision reducers are compatible with most servo motor manufacturers and the catalog provides specific dimensions for mounting, providing necessary design flexibility for the reader.

Contact Nidec Drive Technology to obtain a free copy of the new catalog.

Press Release: 01/06/14

Expansion of Production Capabilities at Itasca, IL facility

Nidec Drive Technology Corporation has recently expanded its assembly capabilities at its Kit Build Center, located in Itasca, IL. The Itasca facility continues to assemble and support their traditional power transmission products, but now the Build Center has added the resources to assemble a common variety of the high precision, servo grade VRT and the right-angle EV planetary series. The added investment allows Nidec DTC to quickly deliver its full core inline (VR) and right-angle (EV) series to our growing distribution channel. Within our channel, we are witnessing a growing demand for these very specific application driven series which are becoming more broadly utilized by machine builders.

Nidec Drive Technology Corporation has recently expanded its assembly capabilities at its Kit Build Center, located in Itasca, IL. The Itasca facility continues to assemble and support their traditional power transmission products, but now the Build Center has added the resources to assemble a common variety of the high precision, servo grade VRT and the right-angle EV planetary series. The added investment allows Nidec DTC to quickly deliver its full core inline (VR) and right-angle (EV) series to our growing distribution channel. Within our channel, we are witnessing a growing demand for these very specific application driven series which are becoming more broadly utilized by machine builders.

The Kit Build Center will support the company’s North and South America sales operations. The Build Center allows Nidec DTC to provide a wide-variety of frame sizes and ratios at minimal lead times that are unparalleled within the industry. The Build Center provides excellent flexibility and availability to support distributors on retrofit projects, OEMs on prototype designs, or emergency situations on equipment in the field.

Press Release: 10/04/13

Dissolution of SHIMPO DRIVES, INC.

Effective August 31, 2013, we will officially dissolve the separate company “SHIMPO DRIVES, INC.” which had been a subsidiary of NIDEC-SHIMPO AMERICA CORPORATION. The business unit was originally structured in that manner for certain operational reasons, which are not applicable as the company became more established. We also want to capitalize on the global NIDEC Group brand, presence, support network and reputation which have become an important part of our growth strategy going forward.

Please note the following;

- All formal documents, reports, invoices, payments, etc. should be addressed to “NIDEC-SHIMPO CORPORATION”. All address and contact information will remain unchanged.

- The Federal Tax ID will change to No. 36-2794492. The Federal Tax ID was previously No. 36-4103897 .

All other aspects of your business relationship with the NIDEC-SHIMPO DRIVES business unit will not be affected. Bank accounts, trade references, D&B number, etc. had been those of the parent, NIDEC-SHIMPO AMERICA CORPORATION, therefore those items will remain unchanged.

The change will be seamless and it will have no impact on the service and support that you receive from NIDEC-SHIMPO AMERICA. If you have any questions or concerns about this change, please do not hesitate to contact NIDEC-SHIMPO.

Press Release: 09/16/13

Planetary Reducer with Exceptional Positional Accuracy

Nidec Drive Technology Corporation is proud to announce the release of its new VRT series. The VRT series sets a new standard for servo motor gear reduction applications that require exceptional torsional rigidity and high positional accuracy. The hub-style output of the reducer has an ISO9409 mounting interface and provides superior flexibility in the mounting of pinions, pulleys, and turntables. The reducer is offered in seven different frame sizes and in a multitude of 1-stage and 2-stage ratios. The larger frame sizes include tapered roller bearings that have better radial and axial load handling characteristics than those bearing commonly utilized in competitor’s design, so improved ratings over those products within its competitive class.

Nidec Drive Technology Corporation is proud to announce the release of its new VRT series. The VRT series sets a new standard for servo motor gear reduction applications that require exceptional torsional rigidity and high positional accuracy. The hub-style output of the reducer has an ISO9409 mounting interface and provides superior flexibility in the mounting of pinions, pulleys, and turntables. The reducer is offered in seven different frame sizes and in a multitude of 1-stage and 2-stage ratios. The larger frame sizes include tapered roller bearings that have better radial and axial load handling characteristics than those bearing commonly utilized in competitor’s design, so improved ratings over those products within its competitive class.

With a backlash rating less than 3 arc-minutes and exceptional torque handling capabilities, the VRT is a high performance, compact, and robust solution for equipment manufacturers. The VRT is often used for larger indexing applications and dial tables, commonly found in metal forming, filling equipment, packaging machinery, and assembly automation systems.

For more details please contact Nidec Drive Technology Corporation.

Press Release: 07/31/13

Now Assembling Food and Washdown Duty Gearbox options in Itasca, IL Build Center

As the global marketplace becomes increasingly competitive, Nidec Drive Technology Corporation continues to raise the bar in terms of product quality, variety, flexibility, and availability – providing a real value to our customers. Our new Wash-down and Food Grade compatible reducers serve as another good example where Nidec DTC is delivering improved value to our customers.

As the global marketplace becomes increasingly competitive, Nidec Drive Technology Corporation continues to raise the bar in terms of product quality, variety, flexibility, and availability – providing a real value to our customers. Our new Wash-down and Food Grade compatible reducers serve as another good example where Nidec DTC is delivering improved value to our customers.

Our most common inline and right-angle planetary and cycloidal frame sizes and ratios can now be quickly assembled with a variety of Washdown or Food Grade Duty options from our North America Kit Build Facility. Features can be selected a la carte, depending on the customer’s specifications and factory environment preferences. Small quantity orders can be assembled, tested, and shipped within 2–4 days. For all other series, frame size and ratio combinations; please contact Nidec DTC for price and availability from our main manufacturing facility.