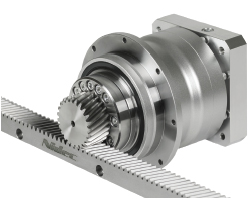

Nidec Drive Technology Corporation has made significant inroads into the machine tool and robotic handling markets globally. Our customers in these markets rely on us daily for our technical expertise in the area of power transmission and have pushed us to supply beyond the gearbox to help enhance the productivity of their machines. Through a partnership with a rack and pinion manufacturer with over 40 years of experience, total drive train solutions are born.

Nidec Drive Technology Corporation has made significant inroads into the machine tool and robotic handling markets globally. Our customers in these markets rely on us daily for our technical expertise in the area of power transmission and have pushed us to supply beyond the gearbox to help enhance the productivity of their machines. Through a partnership with a rack and pinion manufacturer with over 40 years of experience, total drive train solutions are born.

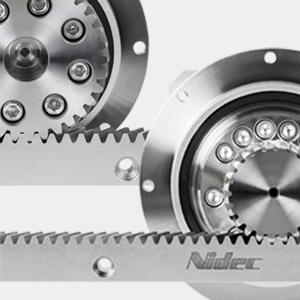

Our ISO 9001/14001 state of the art manufacturing facility performs all critical processes in-house, including cutting, machining, milling, broaching, grinding induction hardening and testing. Pinions and gearboxes are factory assembled and tested as a system, saving our customers valuable time.

We offer a comprehensive lineup of rack and pinion drive systems with exceptional accuracy, system rigidity, feed forces, torque density and efficiency. Each component of the system—gearbox, rack and pinion—is optimized to meet these demands. Although we focus on highly dynamic applications, we also offer more cost-effective options for less challenging axes.

Helical and straight racks are both available, from module 1.5 to module 12, with quality levels from 5 to 10 and lengths up to 3000mm. Our core products are induction hardened and ground, but we can offer a variety of heat treatment and surface finish options. Pinions are offered for keyed shaft or ISO9409-1-A mounting interfaces.

Systems

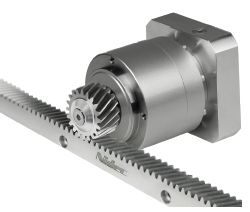

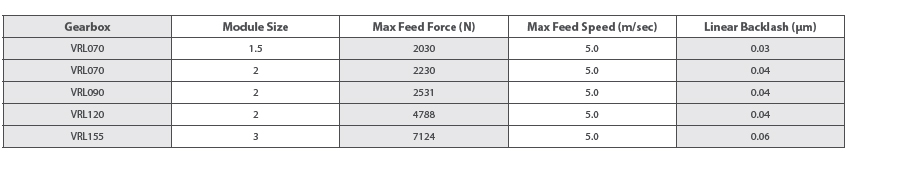

VRL System

- Standard performance system with feed forces up to 7,124N

- Lower requirements for positioning accuracy, rigidity and smoothness

- 23 ratios from 3:1 up to 100:1. Gearbox frame sizes 070-155mm

- Quality 6 rack in 1m lengths. ± 0.035 total pitch error. Induction hardened and ground

- Keyed, shrink fit connection between pinion and output shaft, secured axially with bolt and washer

- Fit for plasma and waterjet cutting machines, welding robots, 7th axis shuttles, gantry and material handling systems

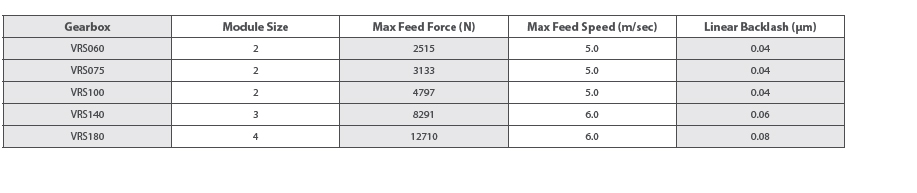

VRS System

- High performance system with feed forces up to 12,710N

- High requirements for positioning accuracy, rigidity and smoothness

- Gearbox frame sizes 060-180mm. Tapered roller bearings for high radial and axial load capacity

- Quality 6 rack in 1m lengths. ± 0.035 total pitch error. Induction hardened and ground

- Keyed, shrink fit connection between pinion and output shaft, secured axially with bolt and washer

- Fit for applications with higher dynamics such as plastic or wood machining centers, CNC routers and pipe bending machines

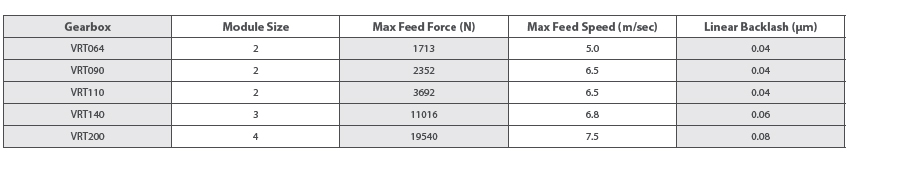

VRT System

- High performance system with feed forces up to 19,540N

- Max requirements for positioning accuracy, rigidity and smoothness

- Gearbox frame sizes 064-200mm. Oversized tapered roller bearings for extreme radial and axial forces

- Quality 6 rack in 1m lengths. ± 0.035 total pitch error. Induction hardened and ground

- Compact ISO 9409 Flange connection with optimal tooth geometry

- Fit for high end machine tool applications such as portal milling machines, turning machines and measurement systems

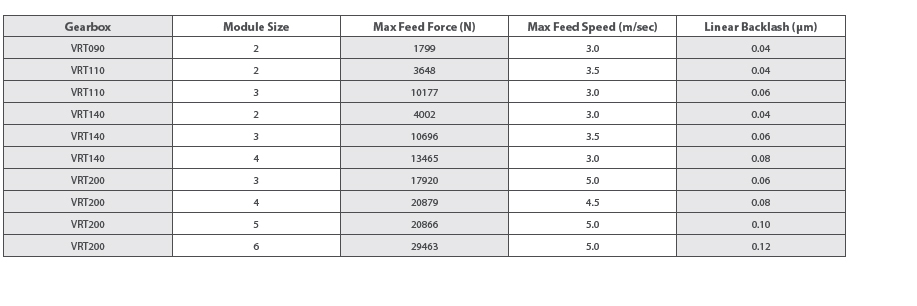

VRT Torque+ System

- Max performance system with feed forces up to 29,463N

- Max requirements for linear stiffness, rigidity and torque density

- Gearbox frame sizes 090-200mm. Oversized tapered roller bearings for extreme radial and axial forces

- Quality 6 rack in 1m lengths. ± 0.035 total pitch error. Induction hardened and ground

- Compact ISO 9409 Flange connection with small pinion. Allows reduction in gearbox frame size and ratio

- Fit for high end machine tool applications such as portal milling machines, turning machines and measurement systems

Components

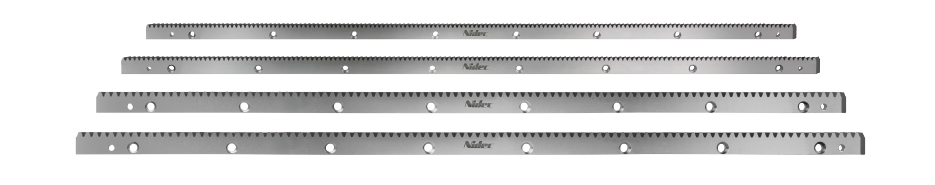

Racks

- Helical or straight cut profiles

- Modules 1.5 / 2 / 3 / 4 / 5 / 6 / 8 / 10 / 12

- Quality levels 5 through 10

- One-piece lengths of 0.5m, 1m, 2m and 3m available

- Materials: SAE 1141, C45E, 42CrMo4, 16MnCr5

- Heat treatments: Case hardening, carburizing with induction hardening and induction hardening. HRC 55-60

- Ground (all surfaces) or milled surface finishes

- Total pitch error as low as ± 0.028

- Readily available: Mod 2/3/4, SAE 1141, Q6, 1m length, ground

Pinions

Keyed Helical Pinion

- Keyed helical pinion with optimized tooth geometry

- Mod sizes 1.5 / 2 / 3 / 4

- Quality level 6

- 20MnCr5 steel composition, case hardened and ground with 60 HRC

- Shrink fit connection ensures reliable positioning of the pinion

- Factory assembled

ISO9409-1-A Helical Pinion

- High precision ISO9409-1-A helical pinion for heavy loads and ultra-high accuracy

- Mod Sizes 2 / 3 / 4 / 5 / 6

- Quality level 5

- 220MnCr5 steel composition, case hardened and ground with 60 HRC

- Compact connection to VRT or EVT gearheads

- High move speeds with low lower input speed using large pitch diameter

- Factory assembled

ISO9409-1-A Small Helical Pinion

- High precision ISO9409-1-A small helical pinion for heavy loads and ultra-high accuracy and exceptional linear stiffness

- Mod Sizes 2 / 3 / 4 / 5 / 6

- Quality level 5

- 20MnCr5 steel composition, case hardened and ground with 60 HRC

- Compact connection to VRT or EVT gearheads

- Small pitch diameter allows reduction of the gearbox frame size and ratio

- Factory assembled