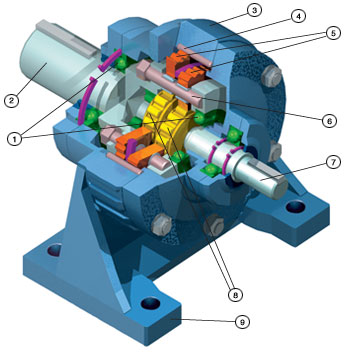

Product Features

Product Features

- Output shaft bearings

- Output shaft

- Internal pin housing

- Internal pin

- Wheels

- Carrier pins

- Input shaft

- Eccentric roller bearings

- Mounting housing

Features and Benefits

| Design Features | Operational Benefits |

|---|---|

| High Efficiency Cycloidal Reducer Design | Single stage reduction ratios up to 71:1 saves spaceRolling motion minimizes friction and wear, reducing heat, resulting in a 95% efficiency rating per stage

500% shock load capability as there are only compressive forces rather than shear forces on the tooth Low speed of cycloidal wheel results in minimal reflected inertia, less wear, and extremely long service life Due to the large overall “tooth / pin” contact area, select a Circulute Reducer using smaller mechanical service factors |

| Two Backlash Ratings | Standard backlash offers the highest available torque rating at an economical pricePrecision backlash results in tighter positional tolerances |

| Multiple Inputs: NEMA C-Face, Servo Square Flange, Shaft Input, Shovel Base, Top Mount | Versatility to fit whatever prime mover is needed for the applicationNEMA and servo input flanges are compact “quill-style” hollowbore configuration, eliminating input couplings and guards

Quill-style input features an input support bearing to control fretting corrosion between motor shaft and reducer hub, and permit tighter internal tolerances NEMA input flange includes threaded back-off holes for easy motor removal |

| Straddle Mount Output Shaft Bearings (sizes D, E, F) | Supports output shaft and drive pins to provide exceptional overhung and thrust load capability, without the need for special bearings or housings |

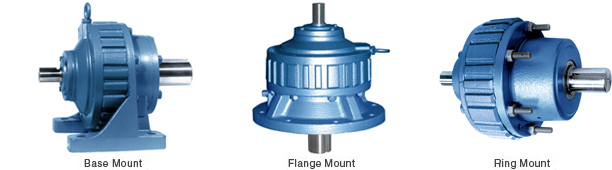

| Multiple Mounting Options: Base, Flange, Ring | Versatility to fit anywhere on your machineRing style allows output bearing to extend well within the machine for greatest overhung load rating |

Mounting Options